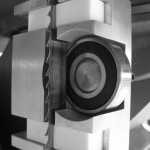

Here’s a set of band saw guides made for my D&W 20″ saw by my friend and neighbor, woodworker/machinist Kim Thoma. We worked on the design together, and Kim did the work on his Bridgeport and lathe. The configuration is similar to the Wright and Davis & Wells guides, which place a stationary guide pad just above and just below the thrust bearing. The upper guide was the prototype — perfectly functional but a little clunky — which served as the jumping off point for the lower guide (still not perfect, but more refined than the upper). The guide body is aluminum, the pads are off-the-shelf 1/2″ x 1/2″ ceramic blocks. So far, these have worked exceedingly well — from my perspective, better than any commercial guides I have ever used.

TIRES

When the D&W 20″ came into my possession a couple of years ago, the tires were grooved and flat from long use with narrow bands. I should have trued and crowned them then, but chose to wait and see how they behaved in use. And they worked OK, in a ‘if-it-ain’t-broke…’ kind of way, so it wasn’t until I started noticing some vibration and inconsistencies in the cut that I decided it was past time to true and crown the tires. To do it, I set up a steady rest that allowed me to present the edge of a turning skew chisel to the spinning lower wheel at the proper angle (about 90° to the axis). I was very easy to true the tires — removing those old grooves — and crown them slightly. I do the lower wheel first, then pop both wheels off and spin the upper wheel on the lower axle.

6 Responses to Bandsaw Guides